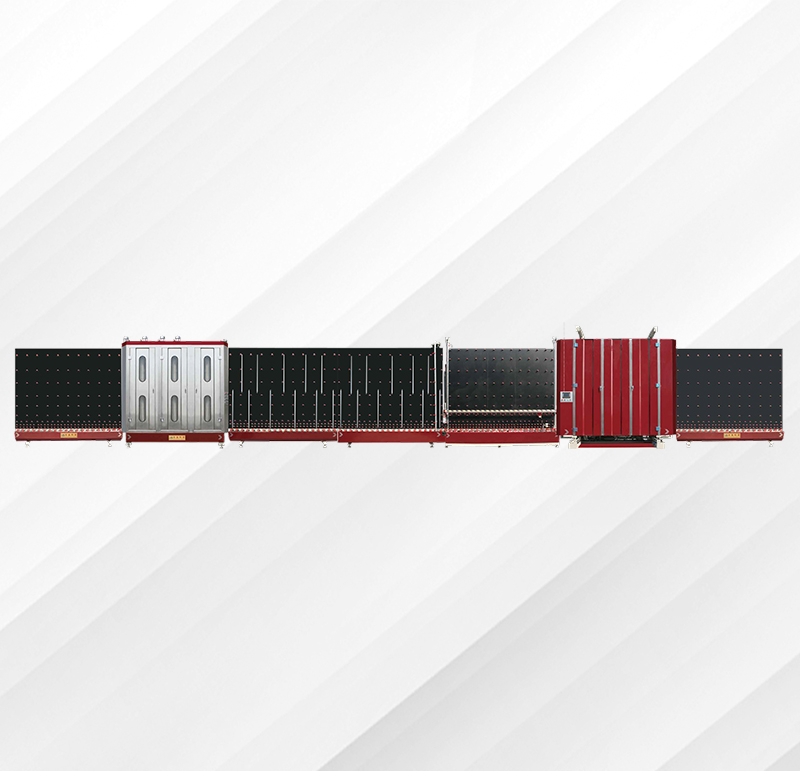

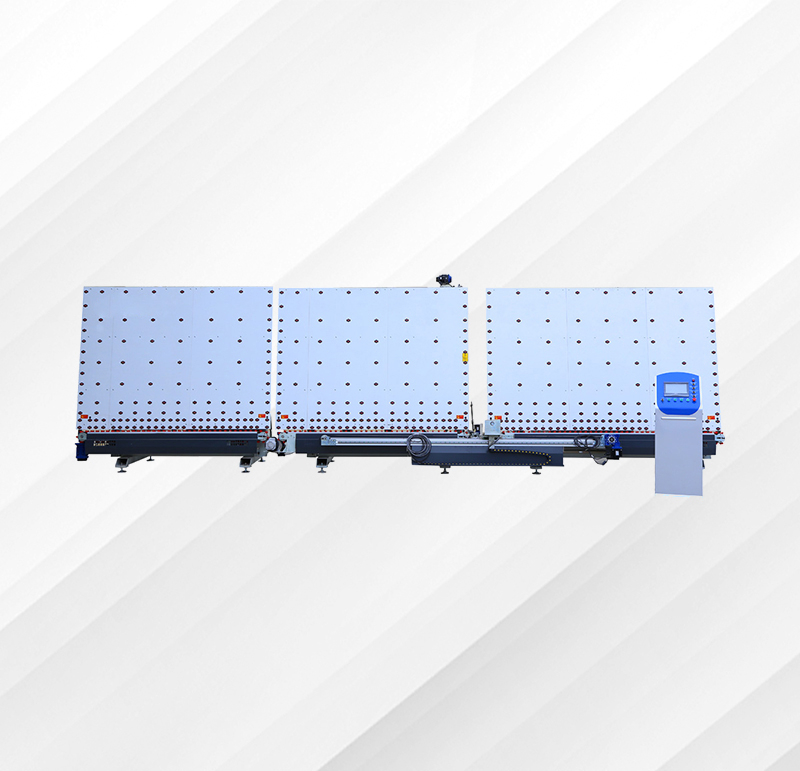

1600型自動(dòng)內(nèi)合片板壓中空玻璃生產(chǎn)線的特點(diǎn)

時(shí)間:2024-04-23 來(lái)源:http://www.kljgg.cn/ 發(fā)布人:昌盛機(jī)械

LBP1600中空玻璃生產(chǎn)線全程采用PLC自動(dòng)控制設(shè)備運(yùn)轉(zhuǎn),觸摸屏操作,動(dòng)作準(zhǔn)備可靠,生產(chǎn)效率高,每日單班八小時(shí)產(chǎn)量達(dá)400塊以上;

The LBP1600 insulated glass production line is fully equipped with PLC automatic control equipment for operation, touch screen operation, reliable action preparation, high production efficiency, and a daily output of over 400 pieces per 8-hour shift;

LBP1600中空玻璃生產(chǎn)線自動(dòng)變頻調(diào)速,實(shí)現(xiàn)低速清洗和高速傳送的率應(yīng)用;

The LBP1600 insulated glass production line has automatic frequency conversion and speed regulation, achieving efficient application of low-speed cleaning and high-speed transmission;

LBP1600中空玻璃生產(chǎn)線采用氣動(dòng)系統(tǒng)驅(qū)動(dòng)板壓動(dòng)作,,并且氣懸浮傳送玻璃;

The LBP1600 insulated glass production line adopts a pneumatic system to drive the plate pressure action, which is efficient and energy-saving, and the glass is transported by air suspension;

LBP1600中空玻璃生產(chǎn)線采用兩對(duì)毛刷兩道清洗的結(jié)構(gòu),適合清洗3-12mm的普通、鍍膜、LOW-E玻璃;

The LBP1600 insulated glass production line adopts a structure of two pairs of brushes and two cleaning passes, suitable for cleaning 3-12mm ordinary, coated, LOW-E glass;

備注:清洗時(shí)水由水泵從水箱抽出,通過(guò)噴淋水管水嘴噴到玻璃表面上,經(jīng)毛刷清洗玻璃后,再流回水箱,循環(huán)使用。漂洗水箱配有帶溫控的水加熱裝置,可自動(dòng)保持水溫。若水質(zhì)較差,用戶需配備水處理裝置,水經(jīng)水處理后進(jìn)入漂洗水箱,按上述步驟循環(huán)使用。(水處理裝置由用戶自備)

Note: During cleaning, water is extracted from the water tank by the water pump and sprayed onto the surface of the glass through the spray pipe nozzle. After cleaning the glass with a brush, it flows back to the water tank and is reused. The rinsing water tank is equipped with a temperature controlled water heating device that can automatically maintain the water temperature. If the water quality is poor, users need to be equipped with a water treatment device. After water treatment, it enters the rinsing water tank and is recycled according to the above steps. (The water treatment device is provided by the user)

LBP1600中空玻璃生產(chǎn)線可連續(xù)清洗玻璃,機(jī)器自動(dòng)區(qū)分、二塊玻璃,清洗等待時(shí)間為零;

The LBP1600 insulated glass production line can continuously clean glass, and the machine automatically distinguishes the first and second pieces of glass, with zero cleaning waiting time;

LBP1600中空玻璃生產(chǎn)線的干燥段采用循環(huán)熱風(fēng)的設(shè)計(jì),保證干燥效果的同時(shí),提高了玻璃清洗速度,更降低了噪音;

The drying section of the LBP1600 insulated glass production line adopts a design of circulating hot air, which ensures the drying effect while improving the glass cleaning speed and reducing noise;

中空玻璃生產(chǎn)線合片平壓機(jī)可移動(dòng)的前壓片內(nèi)采用國(guó)產(chǎn)吸盤裝置(用戶可選裝進(jìn)口吸盤裝置),根據(jù)不同尺寸玻璃 合理分配吸盤工作區(qū)域,基本為單吸盤工作分配保障吸盤有效氣壓,盡可能避免出現(xiàn)玻璃滑落現(xiàn)象。 合片平壓時(shí)采用氣動(dòng)系統(tǒng)驅(qū)動(dòng),運(yùn)動(dòng)采用四點(diǎn)同步齒輪齒條,充分保證兩個(gè)板面平行壓合。對(duì)于加工不同尺寸的中空玻璃設(shè)有調(diào)壓功能,保壓時(shí)間也可根據(jù)玻璃尺寸大小進(jìn)行調(diào)整。

The movable front pressing machine of the hollow glass production line adopts a domestic suction cup device (users can choose to install imported suction cup devices), and the suction cup working area is reasonably allocated according to different sizes of glass. The basic single suction cup work allocation ensures the effective air pressure of the suction cup, and avoids the phenomenon of glass sliding as much as possible. During the flat pressing process, a pneumatic system is used for driving, and a four point synchronous gear rack is used for movement, fully ensuring the parallel pressing of the two plate surfaces. There is a pressure regulating function for processing hollow glass of different sizes, and the holding time can also be adjusted according to the size of the glass.

備注:中空玻璃生產(chǎn)線的內(nèi)合段采用大張開式,檢修便捷,操作更人性化。

Note: The inner sealing section of the insulated glass production line adopts a large opening type, which is convenient for maintenance and more user-friendly for operation.

中空玻璃生產(chǎn)線定位準(zhǔn)確,無(wú)錯(cuò)位現(xiàn)象。平壓段內(nèi)采用知名真空發(fā)生器,吸力大,吸盤真空度在0.8bar以上,分區(qū)域自動(dòng)吸合玻璃,充分保證玻璃吸合后不會(huì)下滑。

The positioning of the insulated glass production line is accurate and there is no misalignment phenomenon. A well-known brand vacuum generator is used in the flat pressure section, with a high suction force and a suction cup vacuum degree of above 0.8 bar. The glass is automatically sucked in by zones, fully ensuring that it will not slide after being sucked in.

LBP1600中空玻璃生產(chǎn)線可生產(chǎn)兩層、三層的中空玻璃。

The LBP1600 insulated glass production line can produce two-layer and three-layer insulated glass.

本文的精彩內(nèi)容由中空玻璃生產(chǎn)線提供,本網(wǎng)站還有很多的精彩內(nèi)容,更多的內(nèi)容您可以點(diǎn)擊進(jìn)入:http://www.kljgg.cn我們有專門的客服為您解答問(wèn)題

The exciting content of this article is provided by the insulated glass production line. There are also many exciting contents on this website. For more content, you can click to enter: http://www.kljgg.cn We have dedicated customer service to answer your questions

- 淺析中空玻璃丁基膠內(nèi)溢及改善方法 2024/09/03

- 臥式丁基膠涂布機(jī):淺析中空玻璃丁基膠內(nèi)溢及改善方法 2024/09/02

- 中空玻璃打膠機(jī)的從屬分類 2024/08/22

- 丁基膠涂布機(jī)升級(jí)設(shè)計(jì)的重要要素 2024/08/19

- 中空玻璃設(shè)備生產(chǎn)線要注意什么? 2024/08/15

- 式中空玻璃設(shè)備的自動(dòng)化磨砂玻璃制造工藝 2024/08/12

- RTEX在全自動(dòng)鋁條折彎?rùn)C(jī)上的應(yīng)用 2024/08/08

- MBS防火玻璃生產(chǎn)線的特點(diǎn)介紹 2024/08/05

- 膠頭前置全自動(dòng)涂膠機(jī)的使用優(yōu)勢(shì) 2024/08/01

- 膠頭前置全自動(dòng)涂膠機(jī)的使用優(yōu)勢(shì) 2024/08/01

產(chǎn)品分類Product categories

產(chǎn)品分類Product categories

聯(lián)系我們Contact us

聯(lián)系我們Contact us

- 咨詢熱線:0531-85717458 13705446998

- 公司地址: 山東省德州市齊河安頭鄉(xiāng)企巢工業(yè)園

- 掃碼聯(lián)系我們:

當(dāng)前位置:

當(dāng)前位置: