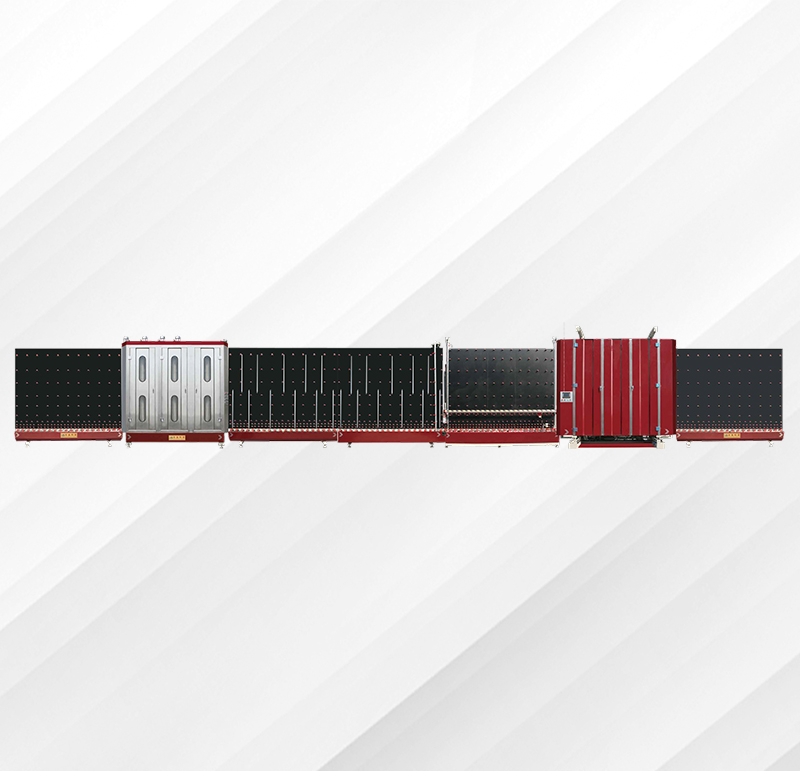

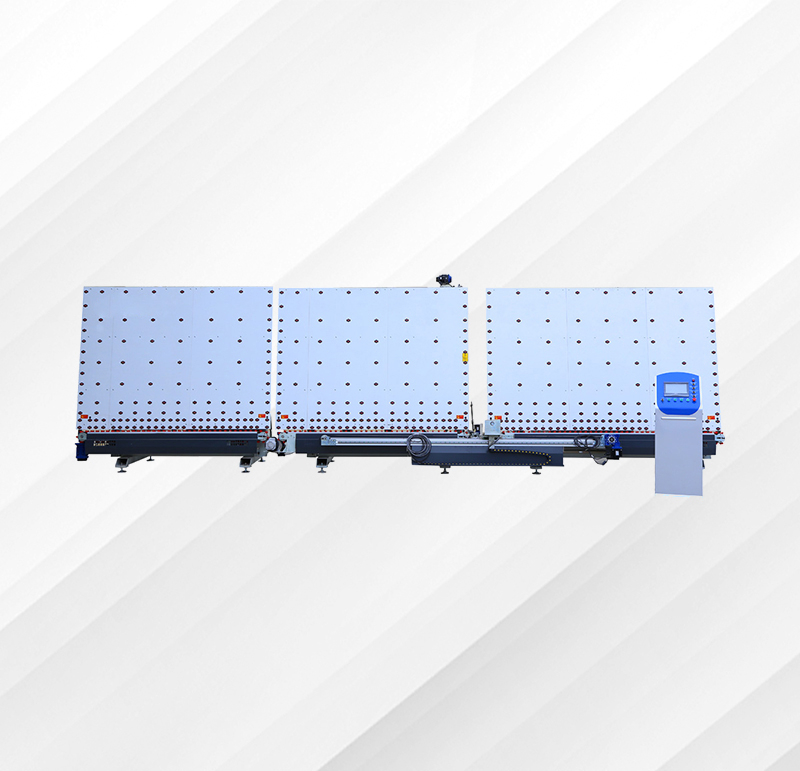

丁基膠涂布機升級設計的重要要素

時間:2024-08-19 來源:http://www.kljgg.cn/ 發布人:昌盛機械

亮點:

Highlights:

1、采用雙機油缸,配有大體積膠缸,可一次性裝載14L丁基膠(2塊正常的¢180mm的丁基膠)。

1. Adopting dual oil cylinders and equipped with large volume rubber cylinders, it can load 14L of butyl rubber (2 pieces of normal ¢ 180mm butyl rubber) at once.

2、增壓系統的主泵采用德國原裝進口麥格思維特(MAXIMATOK)的增壓泵。

2. The main pump of the boosting system adopts the German imported MAXIMATOK boosting pump.

主要性能特點:

Main performance characteristics:

1、該機為半自動涂布機(即人工扶持間隔框進行逐邊操作),變頻調速。

1. This machine is a semi-automatic coating machine (i.e. manually supporting the interval frame for edge by edge operation), with variable frequency speed regulation.

2、將間隔框放在傳送帶上人工扶持框傳送帶運行,通過傳感器時,傳送壓輪及打膠閥按設定程序自動動作。

2. Place the spacer frame on the conveyor belt and manually support it to run. When passing through the sensor, the conveyor pressure wheel and glue valve will automatically operate according to the set program.

3、擺動氣缸動作、壓輪壓下,壓送鋁間隔框行進,當間隔框到達打膠頭時打膠,將膠均勻地涂在鋁間隔框上。

3. Swing the cylinder and press down the pressure wheel to push the aluminum spacer frame forward. When the spacer frame reaches the glue head, apply glue evenly to the aluminum spacer frame.

4、等間隔框另一側快要到達壓輪時,壓輪抬起,離開打膠頭時,膠閥自動關閉,停止打膠,以上程序由PC控制,時間有人機界面控制,可以觸摸調節。

4. When the other side of the equidistant box is about to reach the pressure wheel, the pressure wheel lifts up and leaves the glue head. The glue valve automatically closes and stops gluing. The above program is controlled by a PC, and the time is controlled by the human-machine interface, which can be adjusted by touch.

5、在設計、選用元氣件以及涂膠效果方面,在國內均屬水平。

5. In terms of design, selection of components, and coating effect, it is at the same level in China.

6、采用PC控制系統,定位、傳送、涂膠均自動完成。

6. Using a PC control system, positioning, conveying, and gluing are all automatically completed.

7、輸送采用變頻調速電機調速,運行速度平穩。

7. The conveyor adopts variable frequency speed control motor for speed regulation, and the running speed is stable.

8、有不泄壓即可自動調定位機構,充分保證涂膠膠頭與隔框兩側間距涂膠均勻。

8. There is an automatic positioning mechanism that can be adjusted without pressure relief, fully ensuring that the adhesive head and the distance between the two sides of the partition frame are evenly coated.

主要技術參數:

Main technical parameters:

擠膠壓力:12-14Mpa

Squeezing pressure: 12-14Mpa

電源:380V

Power supply: 380V

打膠溫度:100-140度

Glue temperature: 100-140 degrees Celsius

總功率: 2.5Kw

Total power: 2.5Kw

氣動壓力:0.5-0.8Mpa

Pneumatic pressure: 0.5-0.8Mpa

膠頭可調范圍:4-20mm

Adjustable range of adhesive head: 4-20mm

打膠速度:22米/分鐘

Glue application speed: 22 meters per minute

外形尺寸:3000*700*1236mm

Dimensions: 3000 * 700 * 1236mm

總重量:850kg

Total weight: 850kg

- 淺析中空玻璃丁基膠內溢及改善方法 2024/09/03

- 臥式丁基膠涂布機:淺析中空玻璃丁基膠內溢及改善方法 2024/09/02

- 中空玻璃打膠機的從屬分類 2024/08/22

- 丁基膠涂布機升級設計的重要要素 2024/08/19

- 中空玻璃設備生產線要注意什么? 2024/08/15

- 式中空玻璃設備的自動化磨砂玻璃制造工藝 2024/08/12

- RTEX在全自動鋁條折彎機上的應用 2024/08/08

- MBS防火玻璃生產線的特點介紹 2024/08/05

- 膠頭前置全自動涂膠機的使用優勢 2024/08/01

- 膠頭前置全自動涂膠機的使用優勢 2024/08/01

當前位置:

當前位置:

產品分類Product categories

產品分類Product categories

聯系我們Contact us

聯系我們Contact us