中空玻璃加工設備的組成結構

時間:2024-05-07 來源:http://www.kljgg.cn/ 發布人:昌盛機械

中空玻璃加工設備的組成結構

Composition and structure of insulating glass processing equipment

以下有八種全自動加工生產中必不可少的機器設備,具體如下:

There are eight essential machine equipment in fully automatic processing and production, as follows:

1、切割機(鋼化中空不選)

1. Cutting machine (tempered hollow not selected)

切割機是用于玻璃原片的切割,根據生產玻璃的規格設定切割大小及形狀。

A cutting machine is used for cutting glass raw materials, and the cutting size and shape are set according to the specifications of the produced glass.

2、磨邊機(可不選)

2. Edge grinding machine (optional)

主要用于普通 平板玻璃底邊和倒角的磨削,拋光。是玻璃機械深加工設備中廣泛用到的冷加工設備之一。

Mainly used for grinding and polishing the bottom edge and chamfer of ordinary flat glass. It is one of the widely used cold processing equipment in glass machinery deep processing equipment.

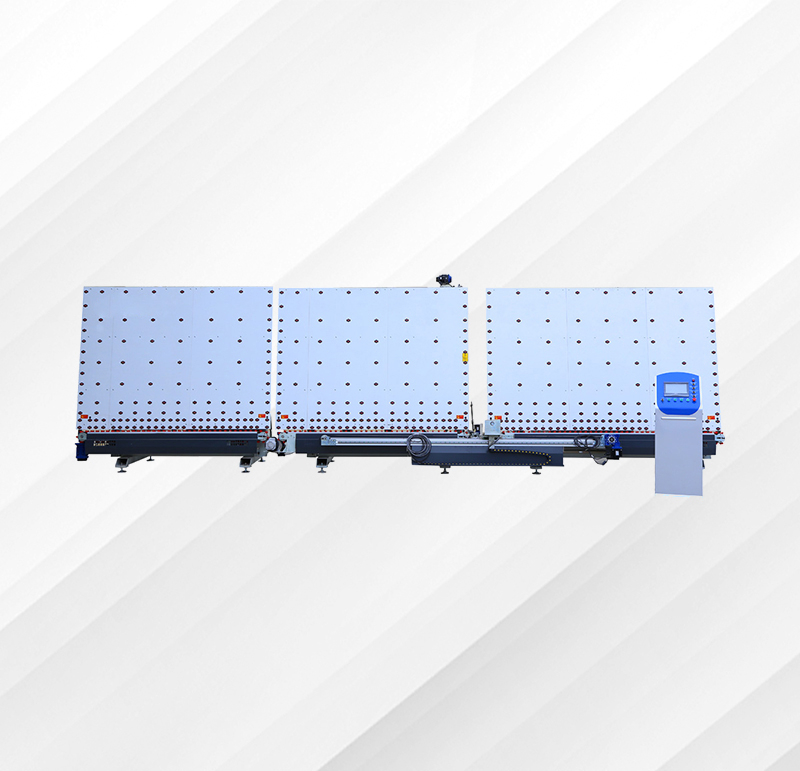

3、玻璃清洗機

3. Glass cleaning machine

玻璃清洗機是一種的玻璃清洗烘干的必要設備,現在多數使用立式清洗機,可以對玻璃進料、清洗、烘干、出料進行連續生產,每段進行獨產設置運行速度,即簡單又快速。清洗機采用不銹鋼材質,雙層底板,激光一體成型技術,上傳動方式,不會有漏水現象,傳送系統采用智能變頻調速,實現清洗機的率應用。采用高壓循環風機,雙風刀雙風機,提高風干質量及效率。耐高溫1010刷絲,可輕松清洗LOW-E及鍍膜玻璃

Glass cleaning machine is a necessary equipment for efficient glass cleaning and drying. Nowadays, most vertical cleaning machines are used, which can continuously produce glass feeding, cleaning, drying, and discharging. Each section is set with a separate production speed, which is simple and fast. The cleaning machine is made of stainless steel material, with a double-layer bottom plate and laser integrated forming technology. It is driven by an automatic transmission method, and there will be no water leakage. The transmission system adopts intelligent frequency conversion speed regulation to achieve efficient application of the cleaning machine. Adopting high-pressure circulating fans, dual blades and dual fans to improve air drying quality and efficiency. High temperature resistant 1010 brush wire, easy to clean LOW-E and coated glass

4、玻璃上下片機

4. Glass loading and unloading machine

了玻璃在人工上片搬動中有可能性造成的傷害和財產損失,實現玻璃生產的智能化、全自動化。大幅度減輕了工人的勞動強度,具有投資小,效率顯著等優勢

Solved the potential harm and property damage caused by manual loading and moving of glass, achieving intelligent and fully automated glass production. Significantly reducing the labor intensity of workers, with advantages such as low investment and significant efficiency

5、鋁條折彎機

5. Aluminum bar bending machine

采用數控伺服電機送料,數控折彎角度控制系統。四個儲料槽,可分別存4種不同規格的鋁條。可以折三角、鉅形、正五方形、主邊形、圓弧等形狀。

Adopting CNC servo motor feeding and CNC bending angle control system. Four storage tanks can store four different specifications of aluminum bars. It can be folded into shapes such as triangles, giant shapes, regular pentagons, main polygons, and arcs.

6、分子篩罐裝機

6. Molecular sieve canning machine

是折彎式中空玻璃生產中必有設備,鋁條背面中間打孔,罐裝、自動封膠。

It is a necessary equipment in the production of bent insulating glass, which includes punching holes in the middle of the back of the aluminum strip, canning, and automatic sealing.

可灌裝自動折彎成形鋁框和普通直插角鋁框。在密閉條件下灌裝,了干燥劑水器失效,提率及中空玻璃壽命。

Can be filled with automatic bending formed aluminum frames and ordinary straight angle aluminum frames. Filling under closed conditions solves the problems of desiccant water dispenser failure, increased efficiency, and the lifespan of insulating glass.

6、丁基膠涂布機

6. Butyl adhesive coating machine

丁基膠涂布機是將丁基熱熔膠均勻地涂在中空玻璃的鋁間隔框上。該機為半自動膠條涂布機,即人工扶持鋁間隔框進行逐邊操作。是中空玻璃涂道密封膠的設備。

The butyl adhesive coating machine evenly applies butyl hot melt adhesive onto the aluminum spacer frame of the insulating glass. This machine is a semi-automatic adhesive strip coating machine, which manually supports the aluminum spacing frame for edge by edge operation. It is a device for applying the first layer of sealant to insulating glass.

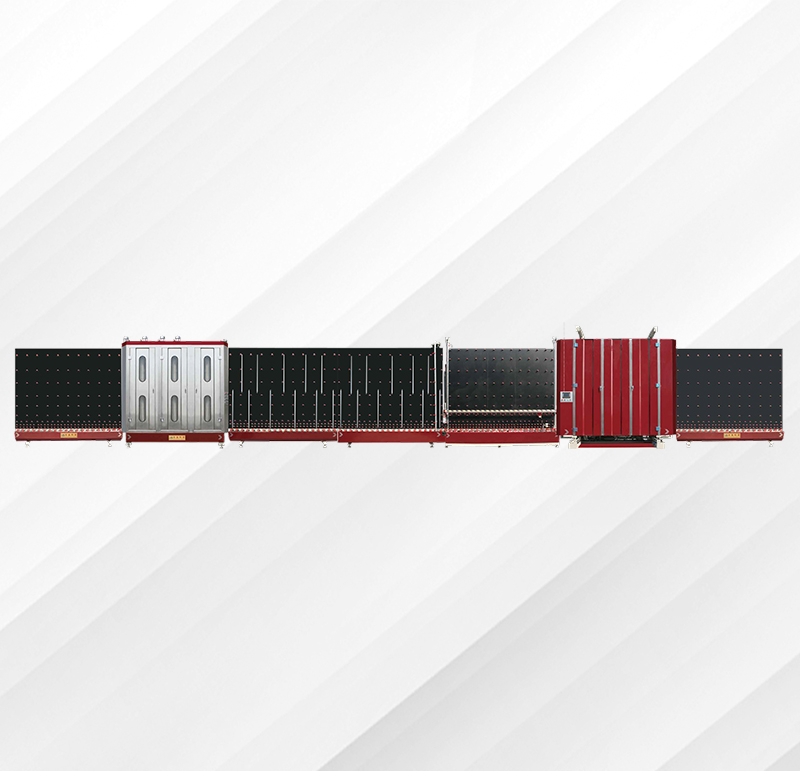

7、合片壓片生產線

7. Composite and pressing production line

清洗好的玻璃通過傳送段到達燈檢段,便于更直觀檢測玻璃的清洗質量。自動傳送合片段上鋁框智能合片,進入板壓段壓合,壓合后的二玻或三玻中空玻璃到下一環節打膠。

The cleaned glass is transported to the lamp inspection section through the conveying section, making it easier to visually inspect the cleaning quality of the glass. Automatic transmission of aluminum frame intelligent lamination on the lamination segment, entering the plate pressing section for lamination, and the pressed two or three glass insulating glass is glued to the next stage.

8、中空玻璃封膠線

8. Hollow glass sealing line

中空玻璃的第二道密封膠,涂膠系統可與生產線相連接,提高生產效率。具有自動補膠自動調膠功能完成省去人工,標準化的流水生產線是人工打膠從質量和成本上是無法比擬的。

The second layer of sealant for insulating glass can be connected to the production line through the adhesive system, improving production efficiency. The automatic glue filling and adjustment function eliminates manual labor, and the standardized production line is incomparable to manual glue application in terms of quality and cost.

本文由中空玻璃加工設備提供技術支持,更多的詳細精彩內容請點擊我們的網站http://www.kljgg.cn們將會全心全意為您提供滿意的服務。

- 淺析中空玻璃丁基膠內溢及改善方法 2024/09/03

- 臥式丁基膠涂布機:淺析中空玻璃丁基膠內溢及改善方法 2024/09/02

- 中空玻璃打膠機的從屬分類 2024/08/22

- 丁基膠涂布機升級設計的重要要素 2024/08/19

- 中空玻璃設備生產線要注意什么? 2024/08/15

- 式中空玻璃設備的自動化磨砂玻璃制造工藝 2024/08/12

- RTEX在全自動鋁條折彎機上的應用 2024/08/08

- MBS防火玻璃生產線的特點介紹 2024/08/05

- 膠頭前置全自動涂膠機的使用優勢 2024/08/01

- 膠頭前置全自動涂膠機的使用優勢 2024/08/01

當前位置:

當前位置:

產品分類Product categories

產品分類Product categories

聯系我們Contact us

聯系我們Contact us