中空玻璃打膠機,產品雙組份

時間:2024-07-25 來源:http://www.kljgg.cn/ 發布人:昌盛機械

讓我們一起了解中空玻璃雙組份外道膠的固化基理 。

Firstly, let's understand the curing mechanism of the two-component outer layer adhesive for insulating glass together.

我們知道中空玻璃雙組份膠的主膠A組份本身是不固化的,只有配合一定量的硫化劑以后才會逐步固化,為適當加快膠的固化速度,我門在膠的固化劑中加入一定量的硫化促進劑來加快硫化劑跟主膠的反應速度,當我們人為地為了加速膠的固化而加大固化劑用量比例時,膠雖然提高了硫化的速度但膠的本身質量卻降低了,我們用刀片破開經加速硫化而固化的膠發現,這時的膠要比正常的膠松軟的多,像發泡的海綿。故我們的工人在調配雙組份膠時為了盡可能的保證膠的質量,一定要按標準的比例并充分混均以防止膠局部促進劑含量偏高從而影響中空玻璃的整體質量。

We know that the main component A of the two-component adhesive for hollow glass is not cured itself, and it will gradually cure only when a certain amount of vulcanizing agent is added. To accelerate the curing speed of the adhesive, we added a certain amount of vulcanizing accelerator to the curing agent to accelerate the reaction between the vulcanizing agent and the main adhesive. When we artificially increase the proportion of curing agent to accelerate the curing of the adhesive, although the curing speed of the adhesive is increased, the quality of the adhesive itself is reduced. When we use a blade to break open the cured adhesive after accelerated vulcanization, we find that the adhesive is much softer than normal adhesive, like a foaming sponge. Therefore, our workers must ensure the quality of the two-component adhesive as much as possible when blending it, and mix it thoroughly according to the standard ratio to prevent the local accelerator content from being too high and affecting the overall quality of the insulated glass.

雙組份中空膠在硫化過程中,不同的硫化狀態與其粘結力的關系

The relationship between different vulcanization states and adhesive strength of two-component hollow rubber during vulcanization process

中空玻璃雙組份膠所用的原料,都具有很強的粘結力,但不管粘結力多強的材料其特性都需要特定的符合性能要求的條件下才能實現,我們所用的雙組份膠它的粘結力的產生(跟玻璃及鋁條)是在其加入規定量固化劑后立即涂在所需涂布的部位讓其在所涂布的部位完成從開始硫化———完全硫化的一個過程,如果我們將膠在半硫化狀態下在涂所需部位,則粘結強度就大有影響。

The raw materials used in the two-component adhesive for insulating glass have strong bonding strength, but regardless of how strong the bonding strength of the material is, its characteristics require specific performance requirements to be achieved. The optimal bonding strength of the two-component adhesive we use (similar to glass and aluminum strips) is immediately applied to the desired coating area after adding a specified amount of curing agent, allowing it to complete the process from vulcanization to complete vulcanization at the coating area. If we apply the adhesive to the desired area in a semi vulcanized state, the bonding strength will be greatly affected.

筆者做過這樣一個實驗,準備200片玻璃小樣清洗烘干,將合格的雙組份膠按標準比例一次混均,在同樣的環境條件下每10秒將膠分別涂在試樣用玻璃片上,當涂116片試樣時,膠已失去了粘結能力,放置后分別檢驗膠跟玻璃的粘結力,發現其粘結力隨著硫化程度的加強而減弱,直徹底失去粘結力。回想起以前有一個朋友生產的中空玻璃因尺寸搞錯,有100多片中空玻璃多做而報廢放在露天,半年后發現有部分已經開裂脫膠,有的卻完好如初,朋友百思不得其解,同樣的材料,同樣的工人,同樣的生產工藝,同樣的存放環境,為何會有不一樣的密封效果。真正的原因就是膠配的太多,在不同硫化程度下涂玻璃上的,已經開裂的中空玻璃則是膠在半固化狀態下涂上去的。

The author conducted an experiment where 200 glass samples were prepared for cleaning and drying. The qualified two-component adhesive was mixed uniformly according to the standard ratio. Under the same environmental conditions, the adhesive was applied to the glass samples every 10 seconds. When 116 samples were applied, the adhesive had lost its bonding strength. After one day of storage, the adhesive strength between the adhesive and the glass was tested separately, and it was found that its bonding strength weakened with the increase of vulcanization degree until it completely lost its bonding strength. Recalling a friend's production of insulating glass in the past, due to size errors, more than 100 pieces of insulating glass were scrapped and left in the open air. Half a year later, it was discovered that some had cracked and peeled off, while others were intact. The friend was puzzled as to why the same materials, workers, production process, and storage environment could produce different sealing effects. The real reason is that there is too much glue, which is applied to the glass at different degrees of vulcanization. The cracked insulating glass is coated with glue in a semi cured state.

結論:要使雙組份中空膠粘結力達到狀態必須配合均勻后立即涂中空玻璃上力爭在一分鐘內將膠涂布完畢。

Conclusion: In order to achieve the optimal bonding strength of the two-component hollow adhesive, it is necessary to mix it evenly and immediately apply it to the hollow glass, striving to finish the adhesive coating within one minute.

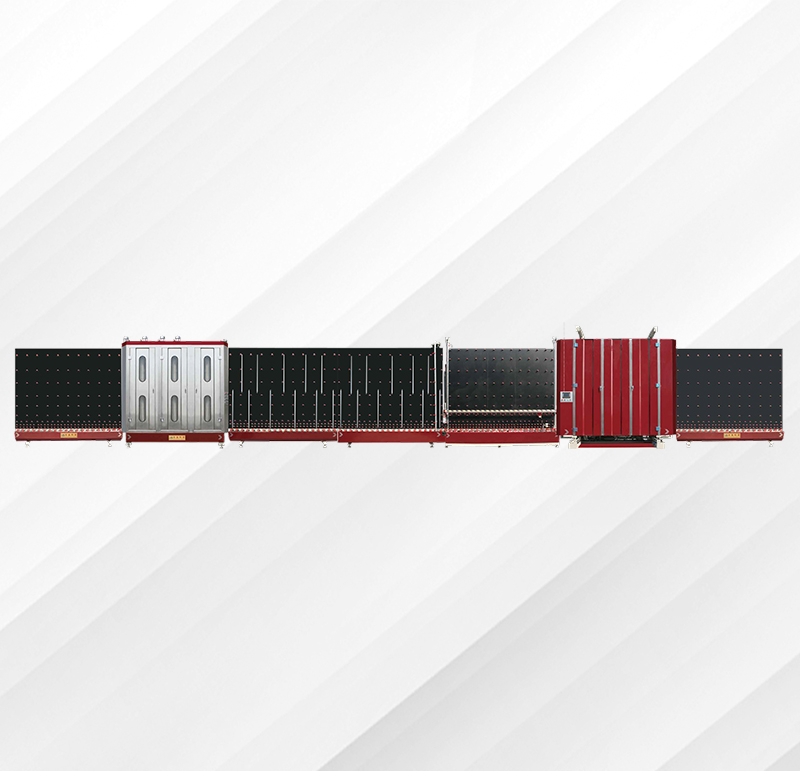

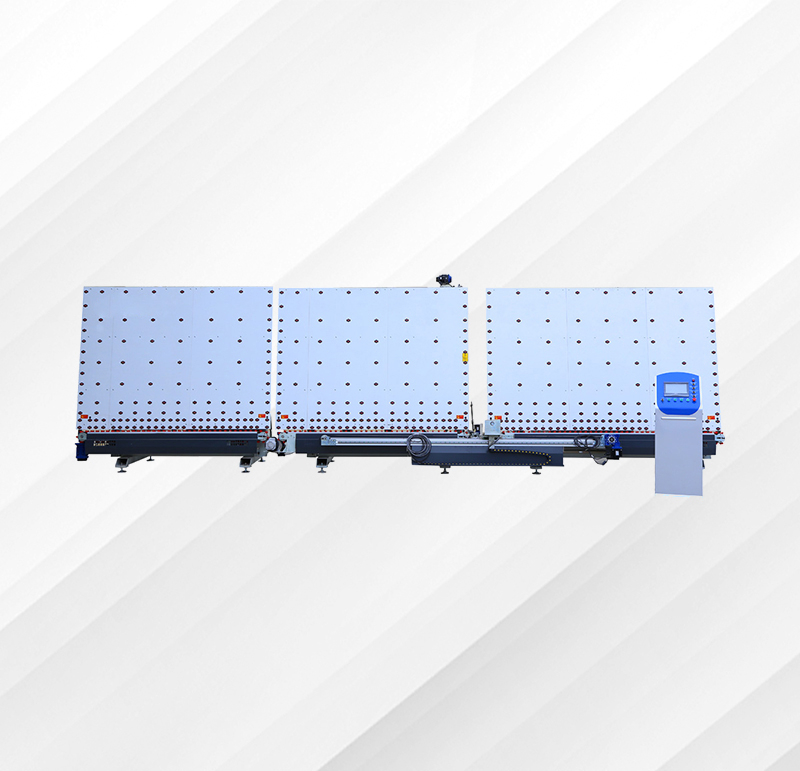

雙組份打膠機的作用:是滿足上述手工刮膠時無法避免的三個缺陷

The function of the two-component glue machine is to first meet the three unavoidable defects during manual scraping of glue mentioned above

一、配比不一致

1、 Inconsistent ratio

二、調配不均勻

2、 Uneven allocation

三、無法使膠在混合后立即涂在中空玻璃上,讓其在玻璃上完成開始硫化完全硫化這一過程

3、 It is not possible to immediately apply the adhesive onto the insulated glass after mixing, and allow it to complete the process of vulcanization from the beginning to complete on the glass

同時經打膠機高壓涂玻璃邊緣上的膠結構密實,而同樣的膠手工混合后涂玻璃上就松軟有氣泡。就像水泥混凝土經震動震實的結構性強,而未經震實的混凝土就算加大水泥的配合量也無法達到所需強度。所以高標準的中空玻璃如幕墻中空都要求必須采用機涂的方式生產。

At the same time, the adhesive structure applied to the edge of the glass under high pressure by the glue machine is dense, while the same adhesive mixed by hand and applied to the glass becomes soft and has bubbles. Just like the structural strength of cement concrete that has been compacted by vibration, concrete that has not been compacted cannot achieve the required strength even if the amount of cement is increased. So high standard insulated glass, such as curtain wall insulation, must be produced by machine coating.

機涂是目前避免手工刮膠四大缺陷的方式

Machine coating is currently the best way to avoid the four major defects of manual scraping glue

目前,世界上雙組份打膠機的使用必須采用配套的雙組份機涂膠,而機涂膠實際上就是經過充分研磨過濾的手涂膠,這種膠流動性好細膩無雜質,可這種膠對膠本身的密封性能關系不大,僅僅是為了配合機器的可操作性能,就是這樣經過精細物理加工的膠,(價比手工刮膠貴2到3元每公斤)在使用時堵塞機器也是常有的事如果用普通手工刮膠放在機器里施工作業不出10分鐘機器就無法工作了。

At present, the use of two-component gluing machines in the world requires the use of matching two-component machines for gluing. Machine gluing is actually hand applied glue that has been thoroughly ground and filtered. This glue has good fluidity, delicacy, and no impurities, but it has little to do with the sealing performance of the glue itself. It is only used to match the operability of the machine. Even for glue that has undergone fine physical processing (2 to 3 yuan per kilogram more expensive than manual scraping glue), it is common for the machine to clog during use. If ordinary manual scraping glue is placed in the machine for construction, the machine will not work for less than 10 minutes.

打膠機,顧名思義它是臺機器,所謂機器就是要比人工生產中空玻璃能提高更多效率的一種設備,可市場上的打膠機除能提高中空玻璃的質量外,提率并不明顯,更有相當多的設備效力還不如人工刮膠高,綜合以上原因得出;

The glue machine, as the name suggests, is a machine that can improve the efficiency of producing insulating glass more than manual production. However, the glue machines on the market not only improve the quality of insulating glass, but also have a considerable amount of equipment effectiveness that is not as high as manual scraping. Based on the above reasons, it can be concluded that;

一、配套用的機涂膠貴

1、 The price of machine glue used for matching is expensive

二、生產效率不高

2、 Low production efficiency

是導致廣大中空玻璃企業有機而不用的主要原因

This is the main reason why a large number of hollow glass enterprises do not use organic materials

一種新型的中空玻璃雙組份打膠機2009年2月已申請

A new type of hollow glass two-component gluing machine has applied for a national patent in February 2009

這種新型的雙組份打膠機克服了世界上公知技術的打膠機的缺陷具有以下特異功能

This new type of two-component gluing machine overcomes the shortcomings of known gluing machines in the world and has the following specific functions

一、能正常涂布所有雙組份中空玻璃膠(包括手工刮膠)

1、 Can apply all two-component insulating glass adhesives (including manual scraping adhesive) normally

二、能提高雙組份膠的結構強度和密實度,從而大大提高中空玻璃的整體質量

2、 It can improve the structural strength and compactness of two-component adhesive, thereby greatly enhancing the overall quality of insulated glass

三、率,目前市場上率的打膠機2臺的工作效率本機一臺就能勝任

3、 High efficiency, currently the most efficient glue dispensing machine on the market, with a work efficiency of 2 units, can handle it with just one machine

如果你擁有了這樣一臺打膠機,那么你就能用普通便宜的手工刮膠生產出每公斤16到17元高檔的機涂膠中空玻璃,提高了產品的整體質量及生產效率,一個熟練工操作機器可涂布800平方以上中空玻璃

If you have such a glue machine, you can use ordinary and cheap manual scraping glue to produce high-end machine coated insulated glass priced at 16 to 17 yuan per kilogram, improving the overall quality and production efficiency of the product. A skilled worker operating the machine can coat over 800 square meters of insulated glass per day

本文由 雙組份打膠機 友情奉獻.更多有關的知識請點擊 http://www.kljgg.cn 真誠的態度.為您提供為的服務.更多有關的知識我們將會陸續向大家奉獻.敬請期待.

This article is a friendly contribution from a two-component gluing machine. For more related knowledge, please click http://www.kljgg.cn Sincere attitude. We provide you with comprehensive services. We will gradually contribute more relevant knowledge to everyone. Please stay tuned

- 淺析中空玻璃丁基膠內溢及改善方法 2024/09/03

- 臥式丁基膠涂布機:淺析中空玻璃丁基膠內溢及改善方法 2024/09/02

- 中空玻璃打膠機的從屬分類 2024/08/22

- 丁基膠涂布機升級設計的重要要素 2024/08/19

- 中空玻璃設備生產線要注意什么? 2024/08/15

- 式中空玻璃設備的自動化磨砂玻璃制造工藝 2024/08/12

- RTEX在全自動鋁條折彎機上的應用 2024/08/08

- MBS防火玻璃生產線的特點介紹 2024/08/05

- 膠頭前置全自動涂膠機的使用優勢 2024/08/01

- 膠頭前置全自動涂膠機的使用優勢 2024/08/01

當前位置:

當前位置:

產品分類Product categories

產品分類Product categories

聯系我們Contact us

聯系我們Contact us